Waterjet cutters are amazing tools that cut any material.

Traditionally, waterjet cutters have been out of reach for the individual or small business because of the high cost and massive size of the machines.

Popular fabrication tools on the market like 3-D printers and laser cutters, can only work with plastics and other soft materials. CNC machines are great for complex shapes but struggle with cutting flat sheets. Unlike them, WAZER can cut through sheets of any material including metal, stone, ceramic, composites, plastic, rubber, and foam. It cuts the materials the world is made of, and is great for professional-grade fabrication.

The original idea began as a senior design project at Penn Engineering, because we needed an easy-to-use tool that could make precision cuts in hard materials. While there, we conducted early research into low-cost waterjet technology.

The response was incredible, and after a few years of developing our engineering skills at more established companies, we decided to focus full time on building out the first desktop waterjet.

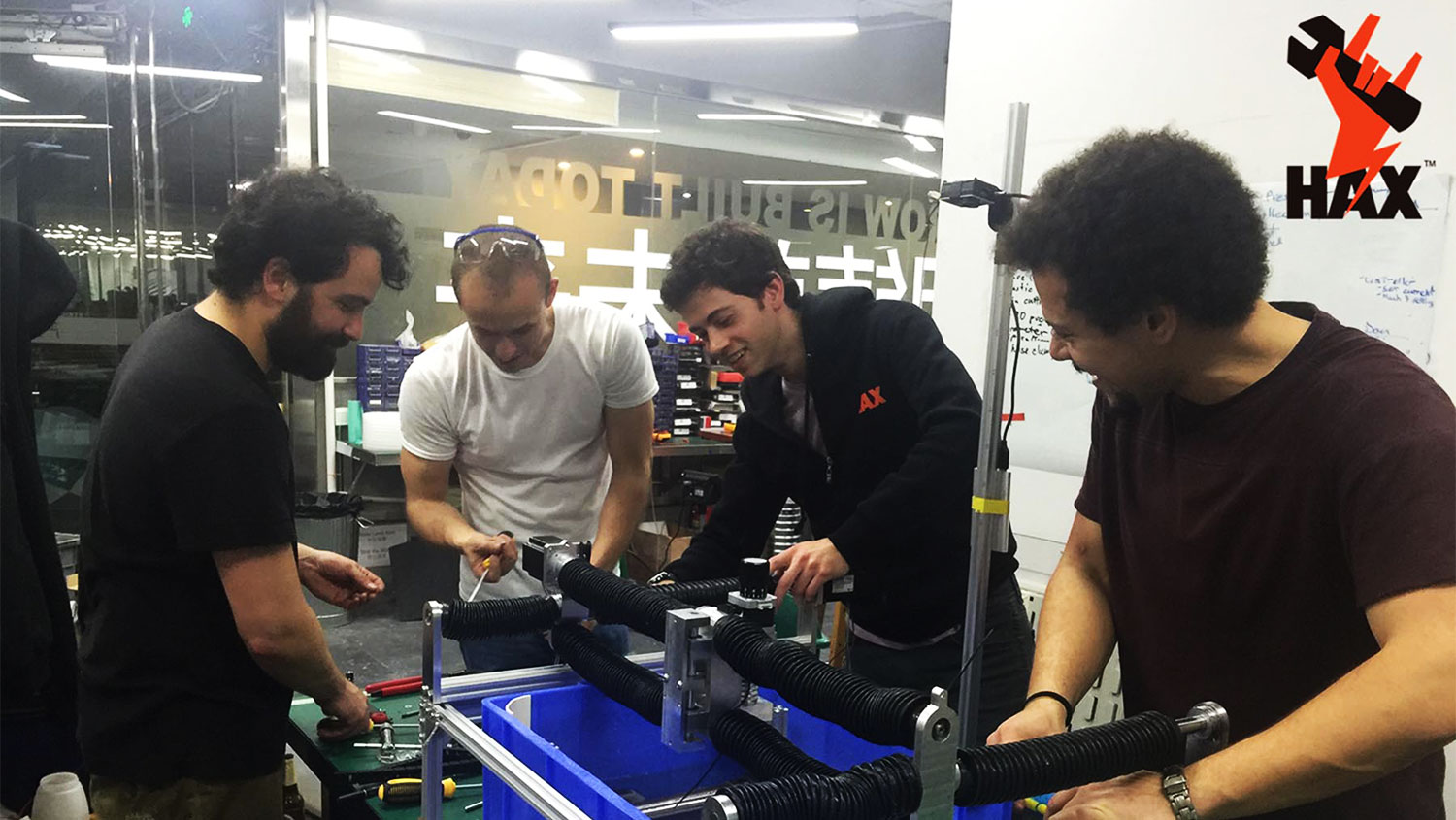

We spent most of 2016 in Shenzhen, China developing the business and further iterating on the design and engineering of WAZER as part of HAX, the world's first and largest hardware accelerator.

“We’re thrilled to be offering WAZER at a price that’s within reach for the individual hobbyist, maker, and small business. As makers, we are excited to use this tool ourselves, and we are eager to see what you will use it for!

- Nisan and Matt”

We are a team of mechanical, electrical and manufacturing engineers.

Collectively we have led the designs of multiple products both at startup and large companies, with hundreds of thousands of units shipped. We have experience managing overseas manufacturers, local suppliers and in-house production. Previous experiences also include working at a local makerspace and operating an industrial waterjet at a custom fabrication shop.

Past Projects

The WAZER founders and early team all met at Penn Engineering, building custom racecars each year for the FSAE international comptetition. We all like to make things whether it's a giant fan-assisted fire-pit, beer, or a trebuchet.

How We Got Here

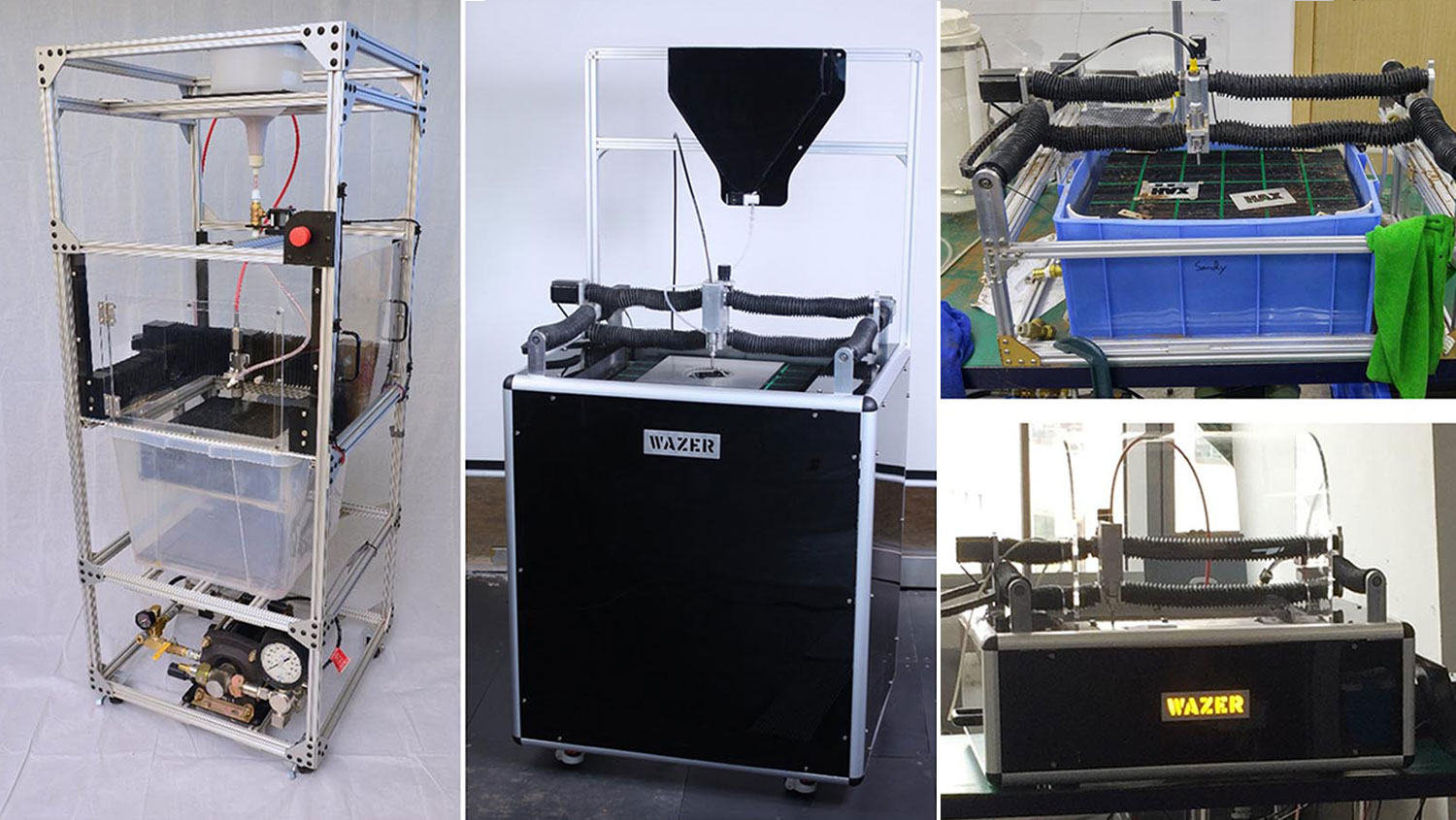

WAZER began as undergraduate research in 2012, where Nisan led a team of students developing low-cost waterjet technology. In early 2015, Nisan and Matt quit their jobs to continue developing the waterjet. In January 2016, Dan and Christian came on-board, and we temporarily moved to Shenzhen, China to join Hax Accelerator, the world's first and largest hardware accelerator.

We worked hard developing WAZER

We assembled a team of engineers

Listened and incorporated various market needs

Built 5 generations of prototypes

Designed the final prototype with production processes in mind

Established relationships with key manufacturing suppliers

Tested the performance on a wide variety of materials

Where We're Going

With our $1.3 million crowdfunding campaign behind us, we're preparing for production and working tirelessly to get the units shipped as soon as possible!