Pump Box Oil Change

The Pump Box oil needs to be changed after the first 50 hours of use, and then every 300 hours after that. These oil changes aren’t done because of the degradation of the oil, but because of the impurities that will find their way into the oil over time. These impurities will result in premature wear if allowed to stay in the oil for extensive periods of time (>300hours).

To replace the Pump Box oil:

1. If you have recently been Cutting with WAZER, allow the Pump Box to cool for approximately 30 minutes before service.

2. If WAZER has not recently been running, turn WAZER on for 30 seconds (i.e. start a Cut and cancel it, or run part of a Tank Cleaning cycle). This will stir up the oil and impurities so they can be removed when you drain the oil.

3. Follow the “Safety Instructions” on the “Cover Opening Procedure” label near the back of the cover. This includes:

• Turn off the water supply.

• Turn off WAZER

• Disconnect the Pump Box Power Cable.

• Disconnect the Pump Box Signal Cable.

4. You can now move the Pump Box to a convenient place to work (i.e. Workbench, table or open floorspace). Remember that this unit is heavy and requires two people to lift or move. Also, the grey sheet metal Pump Box Cover is NOT structural and should not be used as a lift point.

5. For old style pumps (with the thumb screws) loosen (you DO NOT need to remove) the four fasteners that hold the Pump Box Cover on. You should be able to loosen these knobs by hand. Two are located along the back edge and two on the bottom front edge.

For new style pumps, loosen the 4 bolts holding the Pump Box Cover on. They will be in the same location shown above, but require you to use a 4mm Hex wrench to remove the bolts. The bolts will remain attached to the cover so they will only need to be loosened enough so that the cover can be removed.

6. Remove the Pump Box Cover by pulling the bottom front edge forward and lifting top edge up.

7. The Oil Drain Plug is located at the bottom of the crankcase. You will need to find acontainer to collect the drained oil from this location. Prop the Pump Box up so you can slide the container under this plug.

8. Remove the Oil Drain Plug with a 17 mm wrench. Wait for all the oil to drain.

At this point you should take a look at the old oil. It is the best indication of what has been going on inside of the pump. The main problem you are looking for is water in the oil. If you find this contact WAZER support for further information.

9. Replace the oil drain plug and tighten until snug. Wipe the area down of ALL excess oil so that you can assess any leaks or drip later.

10. Remove the yellow Pump Vent Cap.

11. For GP pumps, refill the pump with approximately 15oz (440ml) of included Pump oil, or a Non-Detergent SAE 30 or ISO 100 oil. The oil supplied for your first oil change is General Pump AW Series 100. Please see the bottom of this page for oil recommendations.

Example of a GP pump

12. For KLV pumps, refill the pump with 10oz (300ml) of included KLV pump oil, or 15W-40 engine oil. The oil supplied for your first oil change is Francool APCD15W-40 Engine Oil. Please the bottom of this page for oil recommendations.

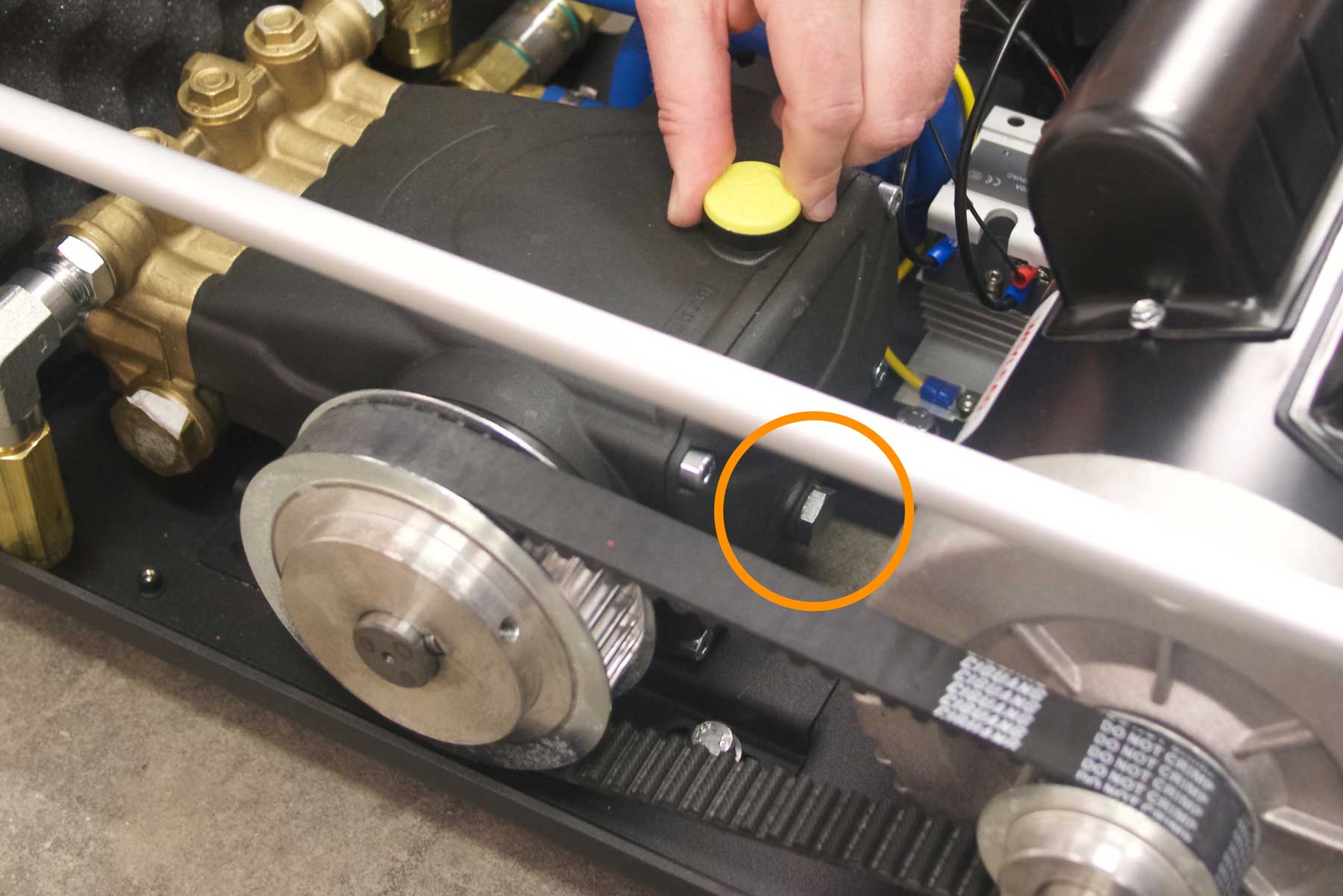

Example of a KLV water pump

The correct oil level is visible in the crankcase window that is located on the opposite side of the pulley. The correct level is in the middle of the window, between the high and low levels.

12. Replace the yellow Pump Vent Cap.

13. Wipe the Pump Box clean of any oil.

14. Replace the cover and tighten the Pump Box Cover Knobs so the cover is securely fastened. Ensure that these are well-secured to prevent unwanted vibration noises and the cover rattling loose during operation.

15. Reconnect and set up the Pump Box:

You’ll need to reconnect the High-Pressure Hose and Water Inlet Hose.

Because you made modifications to water connections, perform a leak test before making any electrical connections.

Connect the Signal Cable between WAZER and Pump Box.

Reconnect the Pump Box Power Cable.

16. Prime the high pressure system. During the oil change process, air will enter the system. Please prime the high pressure system by running a HP Valve output check several times, until air is no longer seen in the water stream.

Recommended Oil For KLV Pump

When choosing an oil to use in your KLV pump, there are a few important things you must consider. The oil must be a 15W-40 grade.

Below are a few brands of oil we recommend using.

Francool APCD15W-40 Diesel engine oil is the oil that will be in the pump when it arrives to you. It is also the type of oil supplied for your first oil change. This will be the OE replacement..

Included WAZER Oil

Francool APCD15W-40

Kubota 15W-40 is verified to be compatible with WAZER KLV pump

Kubota 15W-40 oil

In very special occasion, Kubota 10W-30 engine oil can be used in place of the 15W-40 oil. Revert back to 15W-40 whenever possible.

Kubota 10W-30

Recommended Oil For GP Pump

When choosing an oil to use in your pump, there are a few important things you must consider. The oil must be a non-detergent type and it must be SAE 30 or ISO 100 weight. The bottle should be marked as Pump or Compressor oil, do not use automotive oil in your WAZER.

Below are a few brands of oil we recommend using.

General Pump AW 100 Series is the oil that will be in the pump when it arrives to you. It is also the type of oil supplied for your first oil change. This will be the OE replacement..

General Pump Oil

AW 100 Series

Rarus 427 is the Mobil equivalent of GP AW100, it is a SAE 30 Air Compressor oil and will work great in your WAZER.

Mobil Rarus 427